ADVANCEMENT IN FLUE GAS FLOW MONITORING

- Get link

- X

- Other Apps

The efficient operation of today’s power plant depends largely upon accurate & repeatable measurement of primary and secondary airflow to coal mills, flue gas recirculation flow, overfire airflow, airflow to individual burners, etc.

Flue gas or Stack gas emission flow rate measurement is nowadays important for quantifying emission (CEMS) for environmental reporting for Govt. Authorities for pollution control. Flue gases are gases emitted due to the combustion process due to heating of fuel (liquid or solid or gaseous) & Air with a stoichiometric ratio in:

- Boiler Heating

- Process furnaces

FLUE GAS PRODUCTION DUE TO COMBUSTION MAINLY CONSIST OF :

- Nitrogen (N2)

- Carbon monoxide (CO)

- Carbon dioxide (CO2)

- Traces of Sulphur dioxide (SO2),

- Nitrogen oxides (NO, NO2)

- Particulate matters (SPM)

- Moisture

Flue Gases are gases emitted due to combustion process due to heating of fuel (liquid or solid or gaseous) & Air in:

- Thermal Power Plant

- Steel & Foundries

- Cement production plant

- Chemical & Fertilizer production process plant, many more...

WHY IS FLUE GAS FLOW MEASUREMENT SO IMPORTANT?

As most flue gases emission contains air pollutants that are harmful to human health. So continuous emission monitoring systems (CEMS) are mandatory for providing reporting to state & central pollution control boards for environmental pollution control. It is important to measure the composition and concentration of polluting gases as well as mass flow rates to arrive at the total emission discharge in the environment.

FLUE GAS FLOW RATE MEASUREMENT IS IMPERATIVE FOR BELOW :

- Optimizing ESP performance by maintaining design parameters such as specific collection area, gas velocity, and treatment time within ESP in control.

- Indicates early warning for Preheater condenser failures

- Help regulates harmful pollutants, dust emission controls

- Useful information on optimizing mass balance

- Simple design to operate Helps in energy conservation easily

- Predictive & preventive measures for optimizing their process efficiency and reducing harmful emissions in the environment.

PROCESS CONDITIONS OF FLUE GAS IN STACK :

Process engineers design the lowest possible heat loss into the environment for better thermal efficiency of the power plant. Flue gas process conditions with optimum design have typically as below process parameters:

- Composition: Flue gas with moderate dust/fly-ash particle (Coal-fired).

- Process temperature: 130⁰C to 180⁰C

- Process velocity : recommended approx.12m/s to 20m/s.

WHERE TO MONITOR FLUE GAS FLOW RATE?

To get the optimum efficiency it can be monitored at :

- Chimney or Stack near to the point of sampling for lab analysis.

- Inlet of Flue gas desulfurization plant (Wet FGD / Dry FGD ) in Thermal Power plant

- Process stack in chemical production, fertilizer, steel plants

- Process venting systems

WHICH ARE THE MAIN TECHNOLOGIES AVAILABLE FOR FLUE GAS FLOW MONITORING?

- Differential Pressure based Flowmeter (Aerofoil/ Annubar /Pitot-tube)

- Non-Contact Ultrasonic Flowmeter

- Insertion Thermal Mass Flowmeter

Process instrumentation engineers’ task is to identify which of the above will be the best suitable technology.

BELOW ARE SOME IMPORTANT FACTORS TO BE CONSIDERED & EVALUATED WITH COMPARING TECHNOLOGIES FOR OPTIMUM SELECTIONS:

- Duct or Pipe Dimension

- Insulation thickness, if any.

- Process conditions such as flow rate, pressure, temperature, density, viscosity, dirt & moisture, etc.

- Installation conditions such as horizontal, vertical & available straight lengths, time & effort, etc.

- Accuracy & repeatability needed

- Process turndown ratio needed

- Budgeted price

Based on the above factors process engineer has to understand the working principle, PROS, and CONS of different flow measurement technology & their possibility for selection as mentioned below:

DIFFERENTIAL PRESSURE BASED FLOW METER (AEROFOIL/ANNULAR/PITOT-TUBE) :

WORKING PRINCIPLE

Aerofoil /Annubar / Pitot-Tube works on the principle of measuring differential pressure measurement by creating restriction in the path of flow measures differential pressure across primary flow elements and derives volumetric flow rate. With additional continuous pressure and temperature (instantaneous density) compensation mass flow rate can be derived.

PROS:

- Established Standard BS-1042/ISO 5167 for Volumetric flow measurement

- Suitable up to 5mtrs or higher

- Rugged designed for any process conditions of industries

- Any orientation possible

- Highly Repeatable

- Site calibration easy

CONS:

- Higher pressure drop

- Needs periodic maintenance

- Lower Accuracy 3% FSD & may drift time to time

- Lower turn-down ratio 4:1

- Lower flow sensitivity

- Susceptible to clogging

- High wear factor

- High Installation cost

NON-CONTACT ULTRASONIC FLOWMETER

WORKING PRINCIPLE :

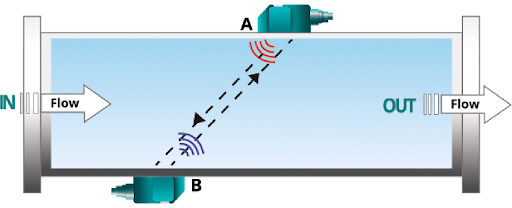

It measures volumetric flow rate consisting of a pair of ultrasonic trans-receiver that transmits and receives ultrasonic pulses across the flue gas path in both directions, resulting in transit time (time difference) is proportional to stack gas velocity. It depends mainly on the sound velocity of the gas.

PROS :

- Derives volumetric flow rate by ultrasonic beam transit-time measurement

- Used for Pipe diameter up to 10 meters

- Suitable for temperature up to max 450⁰C

- Horizontal or vertical orientation is possible

- Turn down ratio better than 100:1

CONS:

- Gas must be dry and clean

- Accuracy up to ±1.5%-3% RD & repeatability ±1%

- High Initial Cost

- Installation need good technical knowledge

- Not suitable for pipes with inner lining

- Drift due to change in flue-gas sound velocity

- Technical knowledge for installation must

INSERTION THERMAL MASS FLOWMETER

WORKING PRINCIPLE :

Thermal mass (calorimetric) flow meters work on the physical principle of thermal dispersion from a heated element to the ambient medium (eg. air or gases). This is affected by the velocity, density (temperature and pressure), and by the characteristic of the medium. The amount of needed energy is a function of the temperature difference ∆T and the mass flow.

Gas flows through two RTD Pt-100 one reference (Tref) and the other Heater (Th). The temperature difference (over-temperature) ∆t between the reference sensor (medium temperature) and the heater sensor is controlled constantly. As per King’s Law, the higher the mass flow rate, the higher the cooling effect of the heater sensor, thus higher the power required to maintain the differential temperature constant. Therefore the heater power is proportional to the gas mass flow rate.

PROS :

- Works on constant calorimetric temperature anemometry (Thermal dispersion)

- Pipe sizes suitable 15mm to 10 meters

- Insertion is rugged and works up to 400⁰C & 16bar or more

- Any orientation possible

- Better accuracy < ±2%RD of mass flow rate

- The highest turndown ratio is 100:1 or better

- Adjustable & versatile

- Lowest pressure drop

- Low cost of ownership against other flow technology

- Online thermal conductivity compensation

CONS :

- Mechanically vulnerable to damage

- Flow straightener recommended

- Affected by high moisture (>10%Vol.) & dirt/dust needs periodic cleaning or purging system

*NOTE: ABOVE ARTICLE DON’T CLAIM ACCURACY AND IT IS FOR GENERAL PROS AND CONS GUIDANCE ON FLOW TECHNOLOGIES AS PER PRACTICAL EXPERIENCE THERE MAY BE IMPROVEMENTS OR DIFFERENT CONFIGURATIONS POSSIBLE FROM DIFFERENT MANUFACTURERS WHICH MAY ELIMINATE SOME DISADVANTAGES.

CONCLUSION :

Considering the above advantages and disadvantages & process conditions concerning different flowmeter technologies for the flue-gas (stack gas) measurement process engineers can decide on suitable flowmeters for optimum performance. Insertion thermal mass flowmeters are a preferable choice for stack diameter up to 8 meters or less with moderate wet or dust load conditions a suitable purging system can be a good & cheaper alternative against DP Type flow meter. Ultrasonic gas flow meters can be a good alternative for large stack diameters above 8 meters against DP & Thermal Flowmeters.

Request to kindly write us your inquiry related to the above application and will happy to assist with flow solutions at our best. For more information log on to https//www.leomi.in & follow us on our LinkedIn page for more updates.

- Get link

- X

- Other Apps

Comments

Post a Comment